二手飞机交易PPI交付检及技术接收Used aircraft transaction PPI delivery inspection and technical reception

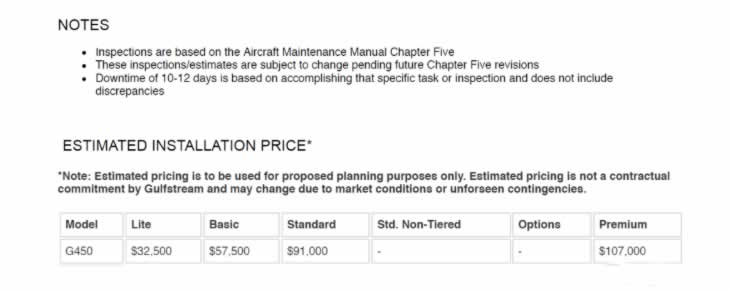

PPI交付检准备及技术接收,其实是非常专业,且技术含量非常高的环节。二手飞机交易PPI交付检及技术接收Used aircraft transaction PPI delivery inspection and technical reception当飞机买卖合同APA已经签署后,买方即可按照APA约定的PPI内容与指定的MRO维修厂商讨PPI维修合同报价及执行时间。以G450为例,不同级别的报价和项目如下所示。一起看一下,了解大致情况。

通过上图所示,PPI的级别有Lite(简捷),Basic(基础),Standard(标准)和Premium(高级)版,级别不同项目不同,价格也就不同,这些都需要在APA中明确。PPI的项目的确定在前面几期的文章已经多次讨论过,是买卖双方根据各自的需求进行利弊权衡和取舍并达到平衡的过程,具体谈判策略可以参考前面几期文章,但其中发动机孔探和试飞项目的确认还是有必要再重申一下。

发动机的寿命周期30%以内孔探发现问题的概率较小,30%-70%的寿命周期内如无异常参数及发动机裕度基本正常的话,一般来说发现问题的概率也较低,如果发动机寿命超过了70%以后执行孔探,即使各项参数正常发现问题的概率也较大,但是如果仅从可靠性和适航角度而言,此时发动机维持正常运转和安全飞行仍然是有足够把握的,特别是成熟发动机,因为发动机的寿命周期是通过可靠性实验验证出来的数据并经过适航当局的验证和批准的且留有余度,当然如果发动机此时的参数已经临近超限的趋势就另当别论了。G450一般发动机硬时限管理的话,10年就需要下发执行中寿检,曾作为某8年的G450的卖方代表,考虑到此原因,谈判时就坚持PPI不执行孔探,后据了解买方在飞机交割后执行发动机孔探中发现问题而导致下发的真实案例。当然有发动机保修协议,买方没有直接的经济损失,但是还是影响后续飞机投入运行的预期而产生间接成本,此案例的买方是买了自用,可能就是想提前发现问题并解决,以减少后面停场时间,故此双方都需要对孔探执行有所考量和取舍。

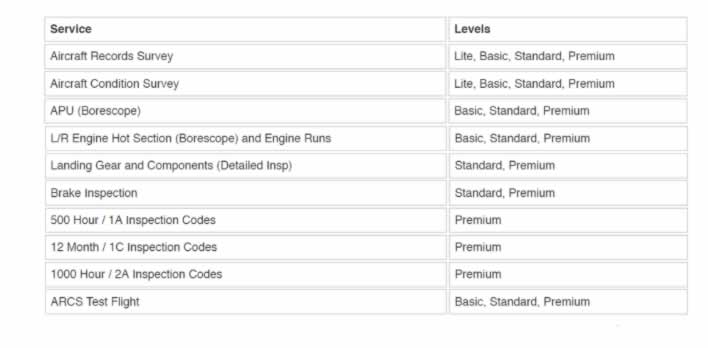

湾流MRO提供的试飞检查单通常按照绿飞机验收标准检验,项目多标准高,超过5年以上的飞机通常很难达到此标准,但此时飞机其实是适航且不影响正常使用的,也就是说日常运行中基本发现不了,比如说客舱渗漏率和引气压力等和飞机系统性能正常衰退相关的项目,试飞就非常容易遇到问题还非常难以解决,如上图所示的客舱渗漏率测试中发现渗漏率为1450Ft/min超过试飞检查单标准1000Ft/min,但实际日常运行并无任何异常现象,因为地面客舱压力测试需要特殊设备比较费时费力,后续将所有的水槽的活门,主登机门的封严全部更换后总算达标,花费了2万多美元,2周时间才得以最终解决;引气压力相关案例可参考——G450APU引气压力偏低分析及放行偏差处理,故此试飞项目清单卖方最好提前了解并评估商讨相关项目的必要性以规避风险。

当买方和指定的MRO维修厂签署PPI的维修合同后,买方即可按照与MRO商定的执行时间与卖方沟通待执行PPI的飞机的调机时间。

调机、试飞、演示飞行

调机和演示飞行(demonstration flight)如果买卖双方人员时间协调得当可以在调机中执行演示飞行,这样可以降低成本并节约时间。调机通常由卖方执行并承担成本;演示飞行通常也是由卖方执行(目的是可以不形成书面的缺陷记录),但是飞行成本(包含飞行员费用,油费,清污水费用,拖车费用,代理费用等所有飞行相关的直接费用,实际操作中也可以在合同中按照经验折合成一个合理的单价进行计算)由买方支付;试飞通常由MRO的试飞员执行,试飞后会形成书面的试飞报告且不可撤销,即试飞中发现的任何与试飞检查单不一致的缺陷或问题原则上都需要进一步检查确认并至少将适航相关的缺陷修复,否则飞机将不适航,适航相关的缺陷修复费用由卖方承担,但试飞员费用和飞行成本由买方承担。以上相关的执行主体和权益成本分摊都应该在APA合同中明确,便于交易过程中相关账单分摊有理有据,曾发生过试飞的燃油费用MRO添加至卖方费用中,因为MRO对此费用分摊并不清楚,后期卖方账单审核时发现并与买方交涉,最终退还约1万美元,故交易过程中双方代表需要熟悉相关条款,以保障己方正当权益。

注:试飞和演示飞行通常只会在当地执行不是国际飞行,飞行员的相关资质只需要满足当地民航法规即可,无需满足注册国要求,如在美国本土试飞或飞行可以只有FAA美国联邦航空局认证的飞行资质即可执行中国注册的B机飞行,无需中国民航局CAAC认证的飞行资质。

PPI执行

PPI执行是买方、卖方和MRO对适航标准,APA合同条款解读和把握的博弈和妥协的过程,因此是整个交易过程中最耗时耗力,谈判最焦灼的阶段,各方的专业能力,谈判技巧和责任心对各自权益影响巨大,总的来说可以按照以下几个原则进行处理:

1、适航标准的把握

如果检查出现任何不适航的缺陷需要找到对应的制造厂依据以明确是否超标,如已明确超标,可以向部件制造厂索要适航标准或替代修理方案,以节约维修成本,因为通常飞机制造厂的适航标准要略高于部件制造厂的适航标准,且部件制造厂可以提供更加深度的维修和更加经济修理方案;

2、APA合同条款把握

因为MRO是收钱单位,他并不在意是买方还是卖方付款,MRO没有动机根据APA合同条款去严格区分具体是买方还是卖方付款,故当有账单产生时,买卖双方都需要依据APA合同条款从源头去判断具体应该谁支付;

3、经济成本与时间成本的平衡

以换代修经济成本最高,但时间成本最低;相反以修代换,经济成本最低,但时间成本最高。买方和MRO通常偏向于前者,卖方则刚好相反,因此各方需要根据PPI整体进度,飞机交易的截止日期,飞机大项费用如融资支付费用、定检费用、时寿件到期更换费用、保险费用、保修协议费用等支付日期,及买卖双方预期的理想交易日期进行综合评估,统筹安排,尽量满足各方利益诉求,以达平衡。下面以两个案例进行说明:

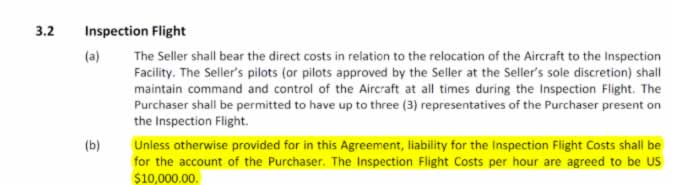

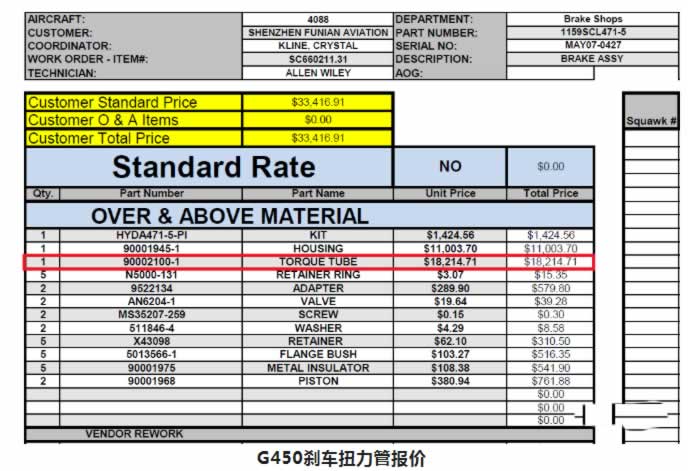

1、刹车扭力管案例

G450刹车扭力管报价

某G450执行PPI时发现刹车扭力管腐蚀超标,单个更换价格为$18,214.71, 4个刹车扭力管全部超标合计更换费用高达7.3万美元。查阅湾流相关手册发现确实无修复依据,考虑到前期和刹车部件制造厂家Megitt有过良好的沟通经历,于是跨过湾流(因为主机厂和部件厂有利益相关,不建议同时联系,以免造成主机厂和部件厂矛盾,不利于解决问题)联系到Megitt工程师并最终获得了修理方案——镀层修复,然后再联系MRO给出部件厂的修理方案,最终得以修复,修理成本差不多只有更换成本的十分之一约8千美元,方案获取周期约两周,修复周期约两周,共计约1个月时间,因为当时APU已经拆下送修,修复周期差不多,因此刹车扭力管修复周期并不影响整体进度。另外此飞机的主轮轮毂和扭力管的情况一致,也是腐蚀超标,与扭力管处理方式一样,不再赘述。

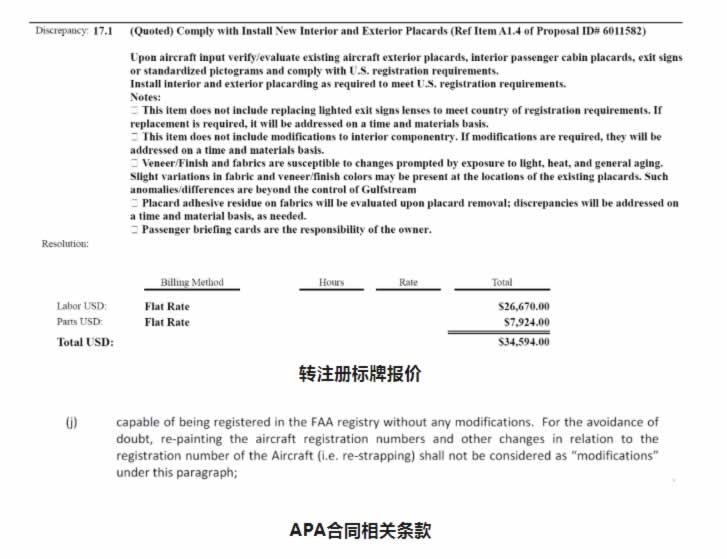

2、转注册标牌费用案例

APA合同相关条款

在卖方账单审核中发现转注册标牌费用报价约3.5万美元,觉得不合理,卖方应当仅对飞机的技术状态负责,飞机转注册的具体操作如英文标牌(此飞机为B机,中文标识需拆下,英文标识需要完善)是否符合FAA要求不应该是卖方责任。卖方根据如上所示的APA合同条款据理力争,认为英文标识应该和喷涂类似,不应该属于Modifications(改装),最终将此账单转移到买方名下,由此可见仔细审查账单和熟悉APA条款有多重要了。

试飞和PPI报告

当MRO执行完试飞和PPI后(无需等试飞和PPI检查发现的缺陷处理完)将形成一个书面的报告同时给买卖双方,买卖双方根据报告中的缺陷描述进行技术接收函(TA)的签署事宜。

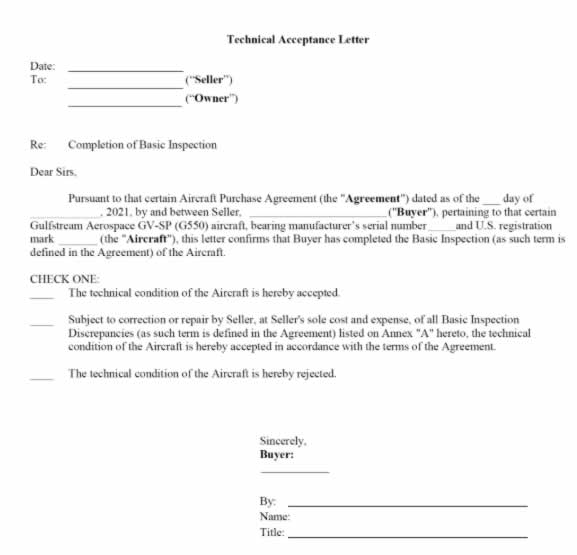

技术接收(TA)

上图所示为技术接收函(TA)样例,技术接收有三种情况:

1,完全接受,无附加条件,此时可以直接进入下一个交易阶段;

2,有条件接受,通常是试飞和PPI报告中的缺陷修复或其他双方一致的条件,此时如果卖方不同意纠正缺陷或条件,将导致卖方违约需要按照APA的违约条款执行,同时卖方需要意识到如果是和适航相关的缺陷是无法拒绝执行的,否则飞机无法适航一直到缺陷合法关闭,当卖方同意修复相关缺陷并支付相关维修费用后,MRO会在修复后出具放行声明或纠正完成报告给买方,即可认为满足接受条件并进入下一个交易阶段;

3,拒绝接受,除非PPI中发现重大缺陷如出现过事故等一般不会拒绝接受,如果买方拒绝接受同样需要按照APA合同中相关条款对违约赔偿和纠纷进行处理并终止交易。

注:TA正常应该在买方获得试飞和PPI报告后按照APA相关条款约定的时限完成签署,而不是等卖方将所有缺陷修复完成后再签署TA。

011.jpg

PPI delivery inspection preparation and technical reception are actually very professional and highly technical links. Used aircraft transaction PPI delivery inspection and technical reception Used aircraft transaction PPI delivery inspection and technical reception After the APA has been signed, The buyer can discuss the PPI maintenance contract quotation and execution time with the designated MRO maintenance factory according to the PPI content agreed by APA. In the case of the G450, the different levels of offers and projects are shown below. Let's take a look and get the general idea.

001.jpg

002.jpg

As shown in the figure above, there are Lite (simple), Basic (basic), Standard (standard) and Premium (premium) versions of PPI, and the prices are different for different levels and projects, which need to be clarified in APA. The determination of the PPI project has been discussed many times in the previous articles, which is a process in which the buyer and the seller weigh the advantages and disadvantages according to their respective needs and achieve a balance. The specific negotiation strategy can be referred to the previous articles, but it is necessary to reiterate the confirmation of the engine hole exploration and test flight project.

The probability of finding a problem is small within 30% of the engine's life cycle. If there are no abnormal parameters and the engine margin is basically normal within 30%-70% of the life cycle, the probability of finding a problem is generally low. If the engine life exceeds 70%, the probability of finding a problem is larger even if the parameters are normal. However, if only from the perspective of reliability and airworthiness, it is still enough to ensure the normal operation and safe flight of the engine at this time, especially for mature engines, because the life cycle of the engine is the data verified by reliability experiments and verified and approved by the airworthiness authority. Of course, if the parameters of the engine at this time are close to the trend of overrun, it is a different matter. G450 general engine hard time management, 10 years need to issue the implementation of life inspection, once as a seller representative of G450 for 8 years, taking this into account, the negotiation insisted on PPI not to perform drilling, and it is understood that the buyer found problems in the execution of engine drilling after the delivery of the aircraft led to the real case of issuance. Of course, there is an engine warranty agreement, the buyer has no direct economic loss, but it still affects the expected operation of the subsequent aircraft and produces indirect costs, the buyer in this case is bought for own use, may want to discover the problem in advance and solve, in order to reduce the stop time behind, so both sides need to consider the implementation of drilling and trade-offs.

006.jpg

The test flight inspection list provided by Gulfstream MRO is usually in accordance with the green aircraft acceptance standard, and the multi-standard items are high, and it is usually difficult for the aircraft more than 5 years old to meet this standard, but at this time the aircraft is actually airworthy and does not affect the normal use, that is to say, it is basically not found in daily operation, such as cabin leakage rate and bleed air pressure and other items related to the normal decline of aircraft system performance. During the test flight, it is very easy to encounter problems and difficult to solve them. As shown in the above figure, the leakage rate of the cabin is found to be 1450Ft/min, which exceeds the standard of the test flight inspection list of 1000Ft/min. However, there is no abnormal phenomenon in the actual daily operation, because the pressure test of the cabin on the ground requires special equipment, which is time-consuming and laborious. It took more than $20,000 and two weeks for the main gate to be finally fixed after all the seals were replaced. Bleed air pressure related cases can be referred to - G450APU low bleed air pressure analysis and release deviation treatment, so it is best for the seller of test flight project list to understand and evaluate the need to discuss related projects in advance to avoid risks.

After the Buyer and the designated MRO repair factory sign the maintenance contract for the PPI, the Buyer can communicate with the Seller the transfer time of the aircraft to be executed by the PPI according to the execution time agreed with the MRO.

Adjustment, test flight, demonstration flight

012.jpg

demonstration flight If the time of the buyer and seller is properly coordinated, the demonstration flight can be performed in the demonstration flight, which can reduce the cost and save time. Switching is usually performed by the seller at its own cost; The demonstration flight is usually carried out by the seller (so as not to form a written defect record), but the flight cost (including pilot's fee, fuel fee, sewage cleaning fee, tow truck fee, agent fee and all other direct costs related to the flight, which can also be converted into a reasonable unit price according to experience in the contract) shall be paid by the buyer; The test flight is usually carried out by the test pilot of MRO, and a written test flight report will be formed after the test flight, which is irrevocable. In principle, any defects or problems found in the test flight that are inconsistent with the test flight inspection list should be further checked and confirmed and at least the airworthiness related defects should be repaired, otherwise the aircraft will be unairworthiness, and the airworthiness related defects repair costs shall be borne by the seller. However, test pilot fees and flight costs are borne by the buyer. The above relevant executive body and equity cost allocation should be clearly defined in the APA contract, so as to facilitate reasonable bill allocation in the transaction process. MRO of the fuel cost that had taken flight test was added to the seller's cost, because MRO was not clear about the cost allocation, the seller found it in the later bill audit and negotiated with the buyer, and finally returned about 10,000 US dollars. Therefore, in the process of transaction, representatives of both parties need to be familiar with the relevant terms to protect their legitimate rights and interests.

005.jpg

Note: Test flights and demonstration flights are usually only performed locally, not internationally, and the relevant qualifications of pilots only need to meet local civil aviation regulations, without meeting the requirements of the country of registration. For example, in the United States, test flights or flights can only carry out Chinese-registered B aircraft flights with flight qualifications certified by the FAA of the United States and without flight qualifications certified by the CAAC of the Civil Aviation Administration of China.

PPI execution

PPI execution is a game and compromise process in which the buyer, seller and MRO interpret and grasp the airworthiness standards and APA contract terms. Therefore, it is the most time-consuming and labor consuming stage in the whole transaction process and the most anxious stage in the negotiation. The professional ability, negotiation skills and responsibility of each party have a great impact on their respective rights and interests.

1. Grasp of airworthiness standards

If there are any unairworthiness defects in the inspection, it is necessary to find the corresponding manufacturer's basis to clarify whether the standard is exceeded. If the standard has been clearly exceeded, you can ask the parts manufacturer for airworthiness standards or alternative repair programs to save maintenance costs, because the airworthiness standards of the aircraft manufacturer are usually slightly higher than the airworthiness standards of the parts manufacturer. And component manufacturers can provide more in-depth maintenance and more economical repair solutions;

003.jpg

2. Grasp APA contract terms

Since MRO is the collecting unit, it does not care whether the buyer or the seller pays. MRO has no motivation to strictly distinguish between the buyer and the seller according to APA contract terms. Therefore, when bills are generated, both the buyer and the seller need to judge who should pay according to APA contract terms from the source.

3. Balance between economic cost and time cost

Replacing the economic cost is the highest, but the time cost is the lowest; On the contrary, the economic cost is the lowest, but the time cost is the highest. The buyer and MRO usually prefer the former, while the seller is just the opposite. Therefore, all parties need to make a comprehensive assessment and make overall arrangements according to the overall progress of PPI, the deadline of aircraft transaction, the payment date of major aircraft costs such as financing payment cost, inspection cost, replacement cost of expired parts, insurance cost and warranty agreement cost, as well as the ideal transaction date expected by both the buyer and the seller. Try to meet the interests of all parties to strike a balance. Here are two examples:

1. Brake torque tube case

007.jpg

G450 brake torque tube quote

When a G450 performed PPI, it was found that the brake torque tube corrosion exceeded the standard, and the single replacement price was $18,214.71, and all four brake torque tubes exceeded the standard. The total replacement cost was as high as $73,000. Referring to the relevant Gulfstream manuals, it was found that there was no basis for repair. Considering that we had a good communication experience with Megitt, the brake parts manufacturer, we crossed Gulfstream (because the OEM and the parts factory have interests, it is not recommended to contact the OEM and the parts factory at the same time, so as not to cause conflicts between the OEM and the parts factory. It is not good to solve the problem) I contacted Megitt engineers and finally got a repair plan -- coating repair, and then contacted MRO to give the repair plan of the parts factory, and finally got the repair, the repair cost is only about one tenth of the replacement cost, about 8,000 US dollars, the solution acquisition cycle is about two weeks, the repair cycle is about two weeks, a total of about 1 month. Because the APU had been removed for repair at that time, the repair cycle was similar, so the repair cycle of the brake torque tube did not affect the overall progress. In addition, the situation of the main wheel of the aircraft and the torque tube is consistent, but also excessive corrosion, and the treatment of the torque tube is the same, no more details.

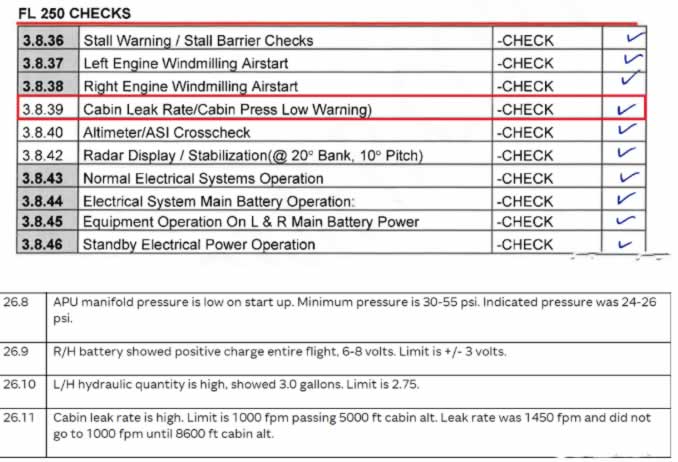

2, transfer registration plate cost case

005.jpg

APA contract terms

In the seller's bill audit, it was found that the cost of the transfer registration plate was about 35,000 US dollars, which was unreasonable. The seller should only be responsible for the technical status of the aircraft, and the specific operation of the aircraft transfer registration, such as the English sign (the aircraft is B, the Chinese sign needs to be removed, and the English mark needs to be improved), whether it meets the FAA requirements should not be the seller's responsibility. According to the APA contract terms shown above, the seller argued that the English marking should be similar to painting and should not be subject to Modifications, and finally transferred the bill to the buyer's name, which shows how important it is to carefully review the bill and familiarize yourself with the APA terms.

Test flight and PPI report

After the MRO completes the test flight and PPI (no need to wait for the defects found in the test flight and PPI inspection to be processed), a written report will be formed and sent to the buyer and the seller, and the seller and the seller will sign the Technical Acceptance letter (TA) according to the defect description in the report.

Technical Reception (TA)

008.jpg

The figure above shows a sample technical reception (TA). There are three types of technical reception:

1, fully accept, no conditions attached, at this time can directly enter the next stage of the transaction;

2. Conditional acceptance, usually the defect repair in the test flight and PPI report or other conditions agreed by both parties. At this time, if the seller does not agree to correct the defect or condition, it will lead to the seller's breach of contract and shall be executed in accordance with the breach clause of APA. At the same time, the seller should be aware that the defect related to airworthiness cannot be rejected. Otherwise, the aircraft will not be airworthy until the defect is legally closed. When the seller agrees to repair the defect and pay the relevant maintenance costs, MRO will issue a release statement or correction completion report to the buyer after the repair, which can be considered to meet the acceptance conditions and enter the next transaction stage.

3, refuse to accept, unless major defects such as accidents are found in the PPI, and generally will not be rejected. If the buyer refuses to accept, it is also necessary to handle the compensation for breach of contract and disputes in accordance with the relevant provisions of the APA contract and terminate the transaction.

Note: TA should be signed in accordance with the time limit stipulated in APA after the buyer obtains the test flight and PPI report, instead of signing TA after the seller has repaired all defects.

版权说明:

1,全面、新鲜的航材资讯及交易概况发布

2,图片及内容涉及侵权,联系微信

3,转载或者引用本文内容请注明来源及原作者;

4,专注二手波音、空客、二手航材等相关领域